Braille & Tactile Signs

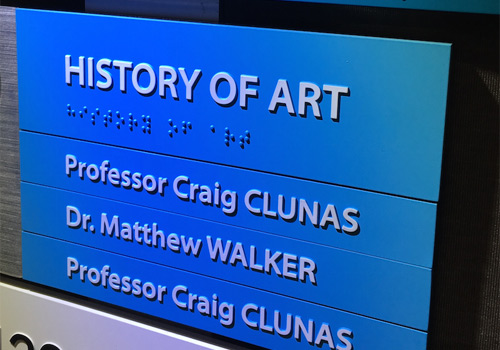

McRobb’s architectural signage includes a range of signs for both internal and external applications. Using an exclusive photopolymer manufacturing process allows us to create a “chemical weld” or integral bond between the 2 surfaces to create DDA compliant, tactile signage on flat and curved surfaces. Our tactile range is manufactured according to ISO 9001 standards and is offered with a 3 year warranty.

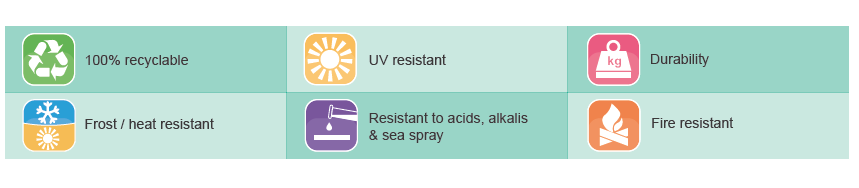

Photopolymer production is particularly suitable for signs that required Braille and tactile characters because of their effectiveness, long-term durability and superior appearance. The impressive look and feel of the substrate and inherent durability makes this a great choice for wayfinding signage that caters for the visually impaired.

In contrast to other production techniques, photopolymer technology creates signs on which all characters and the primary surface are a single structure. Additional layers may be added, and screenprinting or hot stamping can be applied as desired.

Fewer than 1% of the two million visually impaired people in the UK are users of Braille.

Many people lose their sight when they are older and may never learn Braille, but they know how to recognise letters by their shape. For these people, the transition of learning to read tactile letters on a sign, is much easier than learning the new coding of Braille.

Therefore BOTH tactile and Braille are key elements.

The Photopolymer process utilises a polymer material that is light sensitive. It is supplied as a clear blank slate. Photo-negatives are produced with the lettering, pictograms and Braille left clear. The material is exposed with the negatives on top, curing the clear areas of the raised graphics. It then goes through a cleaning process, which washes away all non-exposed areas, leaving the text, Braille and pictograms raised.

Once cleansed the sign is exposed for a second time, post-curing the entire sign. After being painted, it goes through a screen printing process or foiling, called “tipping” where just the tips of the raised areas are highlighted in a separate colour.

Finally, the sign is often satin clear coated, ensuring that the screened area has a non-glare finish, as well as providing an extra layer of protection to the sign and paint.

VHB Tape for mounting, holes drilled/countersunk for mounting.

Finishing: radius corners, bevelled edges, bespoke back plates.

Solid colour backgrounds, metallic and wood effects are all achievable. Digitally printed bespoke backgrounds can also be achieved.

If you would like to make an enquiry, or have any queries regarding our braille & tactile signage service, please do not hesitate to get in touch.

Sign up to our newsletter for inspirational info and updates.

If you would like to make an enquiry, or have any queries regarding our braille signage service, please get in touch today.